- Home

- Latest

- Latest News

- Univacco's Lite Series: Redefining Stamping Film Production

LATEST

Latest News

Univacco's Lite Series: Redefining Stamping Film Production

July 20, 2023

Product Introduction

Univacco's Lite Series: Redefining Stamping Film Production

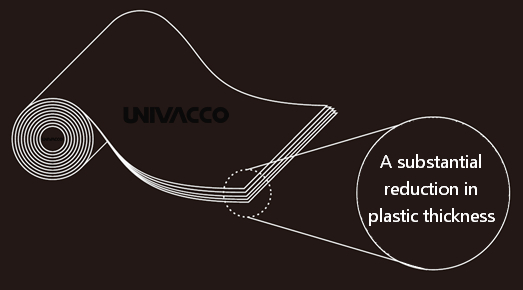

Univacco commitment to sustainability continues with the introduction of the groundbreaking Lite Series, aimed at redefining stamping film production. Guided by the principles of REDUCE, REUSE, RECYCLE, we have developed this innovative product line to minimize plastic waste and carbon emissions. Starting in 2023, our entire range of products will undergo a substantial reduction in plastic thickness, utilizing a lightweight 10.5µm (micron) PET film, resulting in a 4% to 6% decrease in our carbon footprint.

The "light carrier project" ensures the responsible use of materials and maintains compatibility with recycling processes. Our sustainable film production encompasses both hot stamping and cold transfer products, offering a comprehensive solution for environmentally conscious printing.

Through rigorous testing across various printing applications, we have confirmed the stability and effectiveness of our 10.5µm PET-based films. The new carriers maintain optimal stamping and transferring speeds, enhancing workflow efficiency. Additionally, the reduced thickness allows for greater roll capacity, minimizing change-over times and material waste while delivering exceptional embellishment results.

Univacco's Lite Series represents a significant milestone in our ongoing pursuit of plastic and carbon footprint reduction. Experience top-quality stamping film products while actively contributing to plastic waste reduction and carbon footprint mitigation. Together, let's redefine the standards of stamping film production and lead the way towards a more sustainable printing industry.

READ MORE

Sustainability of UNIVACCO |

UNIVACCO is recognized by IECQ QC 080000 |