- Home

- About Univacco

- Sustainability

UNIVACCO is a brand you can rely on to deliver outstanding graphic enhancement. As a worldwide leader in hot stamp and cold transfer foils, it is our responsibility to offer a sustainable product offering.

- Adopt low VOC formulas

- Develop new foil product on a thinner polyester (PET) carrier

- Develop new foil product on post-consumer recycled plastic (PCR) carrier

- Effectively implementing sustainable production

- Increasing the production of water-based formula products

- Using Rotary Type Regenerative Thermal Oxidizer (RRTO) recycling combustion

- Eliminating carbon and VOC emissions

- Reducing energy consumption of manufacturing units

- Environmental Management - ISO 14001:2015

- Greenhouse Gas Management - ISO 14064-1:2018

- Carbon Footprint Requirements & Guidelines - ISO 14067:2018

- Energy Management System - ISO 50001:2018

- Occupational Health and Safety Assessment Series - ISO 45001:2018

- Hazardous Substance Process Management - IECQ QC 080000

- Used solvent is collected, recycled, and re-incorporated into the production process

- Some of our customers return/reuse disposable packaging such as pallets and endplates

- Paper after foiling is 100% recyclable

- Foil-stamped prints(on recyclable paper) are deinkable

- Foil-stamped prints(on compostable paper) are compostable

- Piloting a PET material recycling approach with audited partners in Taiwan

- Residual PET from used foil is turned into recycled PET chips

- Residual PET from used foil is turned into combustible fuel pellets

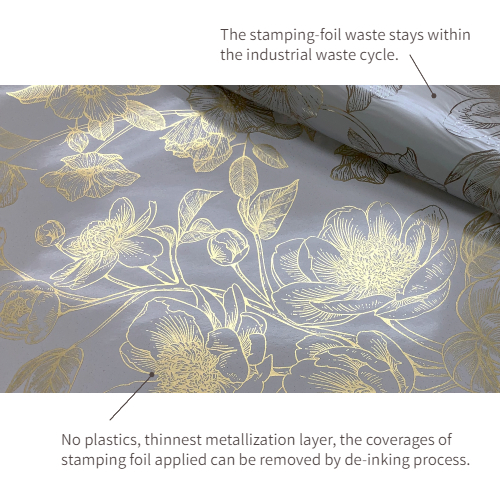

- Stamping foil waste remains within the industrial waste cycle

- Complies with hazard-free regulations.

- Complies with food safety regulations (food contact materials).

- Complies with consumer product safety regulations.

- Complies with toy safety regulations.

- Complies with packaging regulations.

Our answer to global climate change is our launch of an intelligent manufacturing program. This is a comprehensive program which aims to improve our management of natural resource consumption and to reduce carbon emissions.

Hot stamping and cold transfer printing are both RECYCLABLE!

In a study commissioned by the Foil & Specialty Effects Association (www.fsea.com), it was found that paper after foiling is 100% recyclable. The addition of foil creates no problems in deinking or pulping during the recycling process.

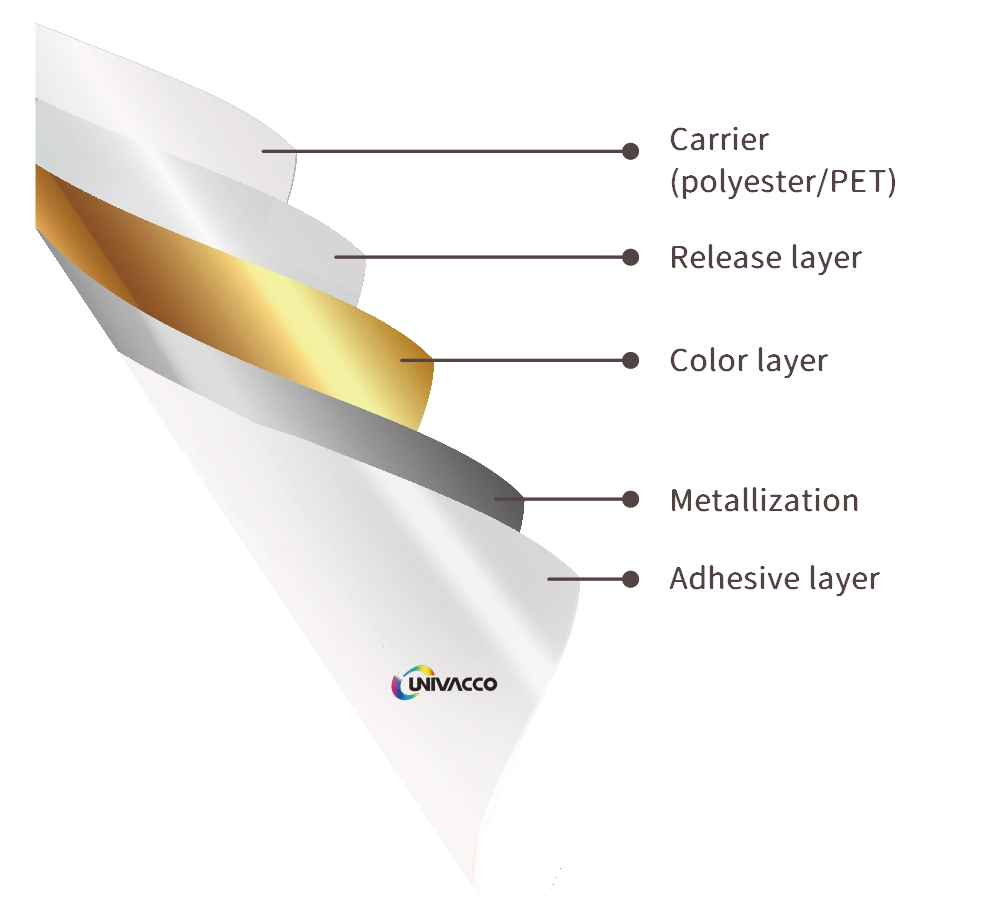

Hot stamping and cold transfer is layered, but also incredibly THIN

In the hot/cold foil structure, aluminum metallization on the transfer layer is extremely thin, and the coating weight is often lighter than conventional inks. After foil stamping or transferring, NO plastic residue remains on the packaging. Unlike laminating films and metallic paper, transferred foil is easily recycled.

|

|

Foil-stamped prints are RECYCLABLE and DEINKABLE

Univacco passed the de-inking certification granted by INGEDE. After stamping with Univacco’s foil, papers can easily be deinked during the re-pulping process, after which the paper can be made into new paper or carton materials without any issues.

Foil-stamped prints are COMPOSTABLE and BIODEGRADABLE

Univacco’s foil has gained DIN CERTCO certification, including both the European Standard EN 13432 and North America Standard ASTM D6400. The certification confirms that, as an additive, our foil is fully compatible with the composting process. After decomposition, substrates decorated by Univacco stamping foil leave no toxic residue or any other negative effect on the environment.

CULTURE DRIVES SUSTAINABILITY

Our company-wide ethical principles of integrity, pragmatism, gratitude, and appreciation guide our development and form the foundation all of our policies, and specifically on sustainability. Thus, UNIVACCO actively commits to the 2030 Sustainable Development Agenda and its Sustainable Development Goals (SDGs) as outlined by the United Nations.

Through our culture, activities, and commitments, our foil not only has the power to brighten packaging designs, but it can also become a beautiful inspiration for our future.